Entegris Phasor II Replacement

Semiconductor Ozone Solutions LLC provides a retrofit replacement solution for the Phasor II Membrane Contactor.

The Entegris Phasor II is a Membrane contactor utilizing pressure differential and surface area of PTFE membrane materials to infuse ozone into DI water. For recirculated DIO3 applications the membrane contactor creates reasonable infusion performance over time. These units are sensitive to pressure variations in DI water. To perform correctly the DI water and Ozone gas pressures must be properly balanced and stable.

Challenges with this membrane contactor are related to the potential for an improper pressure differential to produce ozone bubbles in the DIO3. Ozone bubbles in contact with hydrophobic surfaces causes defects on the silicon surfaces. In addition, if the pressure differential of DI water goes too high with respect to the ozone gas pressure, then damage to the membrane material will result. When the membrane is over pressurized with DI water the hydrophobic membrane can tear or become wetted. When this happens the contactor begins to allow DI water to pass into the ozone gas supply. This can cause damage to the process due to low levels of ozone in the DIO3. In extreme cases the DI water can travel upstream to the ozone generator and damage the ozone delivery system.

Entegris has discontinued manufacturing of this product but SOS has produced an alternative which can be retrofitted in place of these contactors.

SOS LLC DIO3 Infusion Solution

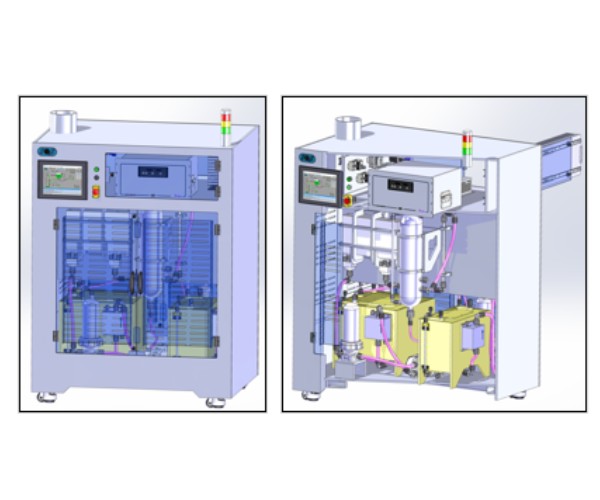

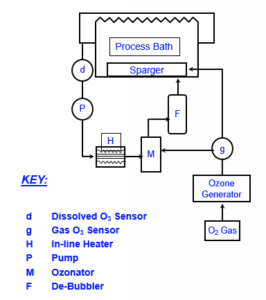

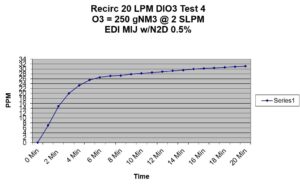

SOS has utilized a completely different infusion method. The SOS infuser also utilizes pressure differential across an infuser assembly, however our infuser does not utilize a membrane material for the ozone to DI Water interface. The SOS solution utilizes an ozone injector with built in check valve. The injector also generates a low pressure zone to allow low output pressure ozone generators to operate with our injection system. The infuser utilizes a PFA coated 316 SS assembly integrated with PFA components. Infusers built from all PTFE/PFA materials are available with longer lead times for DIO3 applications where HF or HCL acids are present. The infuser output is connected to a de-bubbler assembly which vents excess ozone gas back to the recirculation loop and into the process system exhaust. Optional ozone killers are available for excess ozone being vented but are not generally needed due to the higher efficiency infuser being used. Once installed the SOS infusion system ensures bubble free DIO3 without the sensitives of a membrane contactor.

The SOS DIO3 retrofit system is much more efficient and provides a faster infusion than membrane contactors. Utilizing the recirculation pump for infusion pressure the recirculation flow rate can be utilized to maximize the infusion process. Your wet process system software does not require any modifications of the SOS infusion system to properly operate.

Get a Quote

"*" indicates required fields