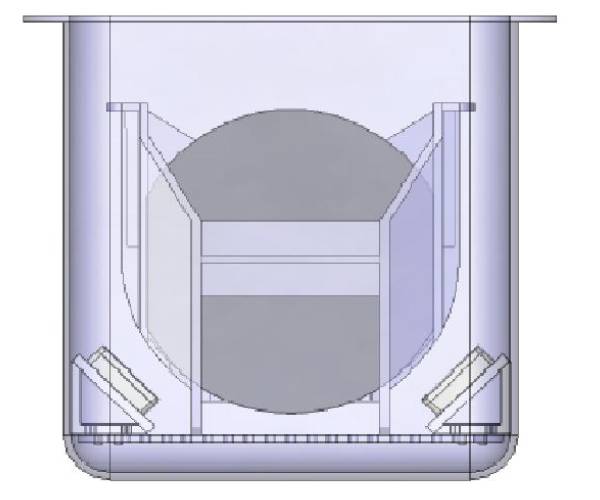

In-Tank CO2 Infuser

Utilizing new techniques in manufacturing S.O.S will produce a static neutralization solution for localized application of pure CO2 gas. Static forces build rapidly within idle rinse tanks. Many product devices are damaged during their initial insertion into rinse water after HF based process steps. By incorporating the Integral Tank Infuser rinse tank charge neutralization can occur preprocess ensuring that wafer yield is maximized.

ESD events can be completely eliminated through the proper utilization of both Integral and In-Line infuser integration. Static charges will build rapidly within the rinse tanks during rinsing. Regardless of tank material of construction these static forces can cause significant damage to product yield. Proper utilization of both in tank and in-line infusers eliminates the damaging effects of ESD (Electro Static Discharge) events while processing.

Advantages

- SOS Infusers provide uniform distribution of the CO2 throughout the rinse water.

- In Tank Infusers maximize CO2 levels by providing a large surface area for CO2 Injection.

- Provide rapid saturation of rinse water minimizing the amount of CO2 gas required to achieve desired PH levels.

- Allows for localized injections which provide additional mechanical agitation improving rinse effectiveness.

- Constructed of chemically compatible materials allows for the injection of various chemical gases. This enables “In-Situ” Processing within a single Rinse Tank, eliminating the need for this additional SC2 Chemical Process Tank.

- Uniform, high volume HCL Injection within rinse tanks is particularly useful in MEMS device creation.

If your yield in the center of the wafer is lower, or you need to accomplish multiple process steps in the same footprint, then you need S.O.S gas infusers integrated today.

Get a Quote

"*" indicates required fields